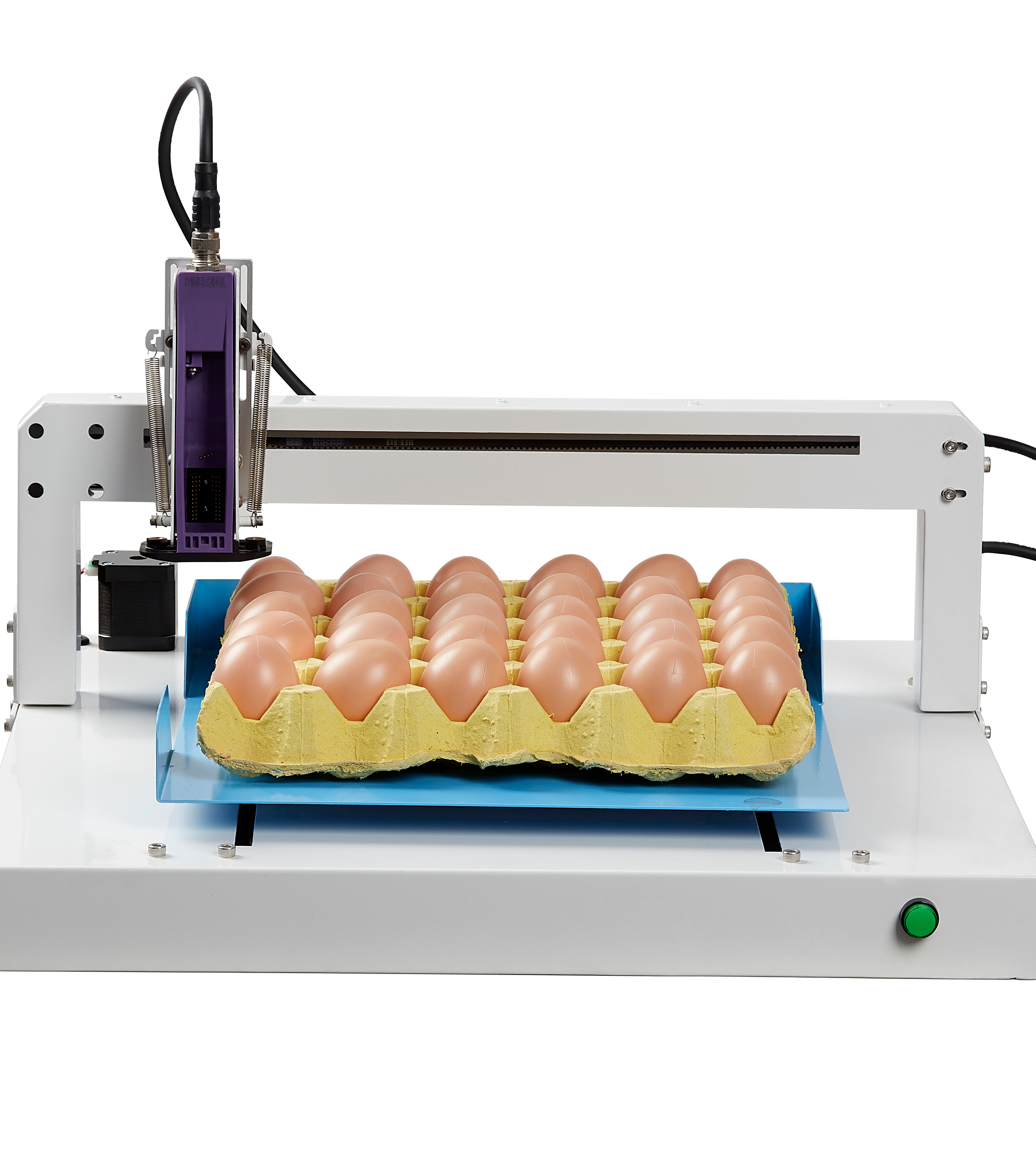

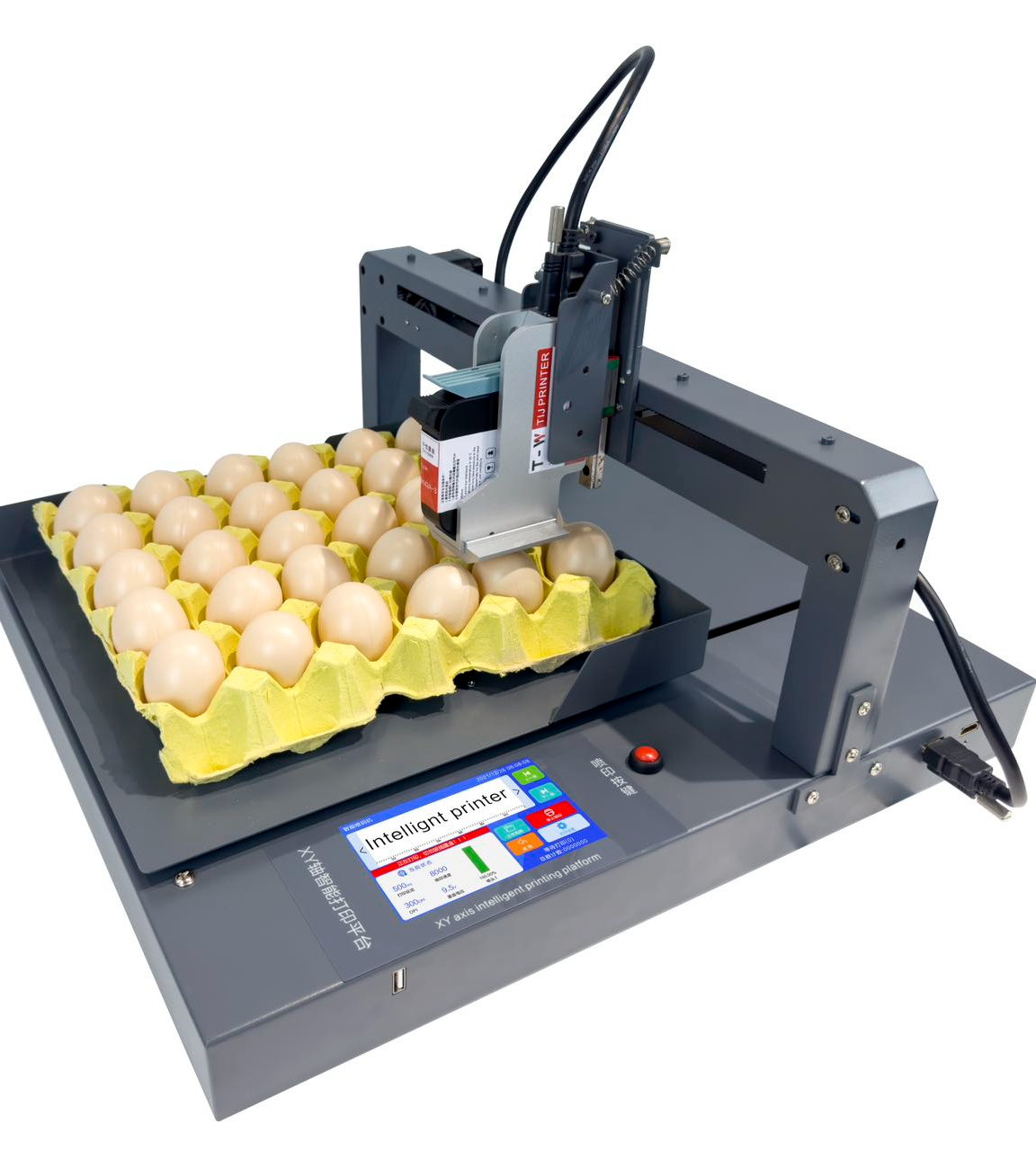

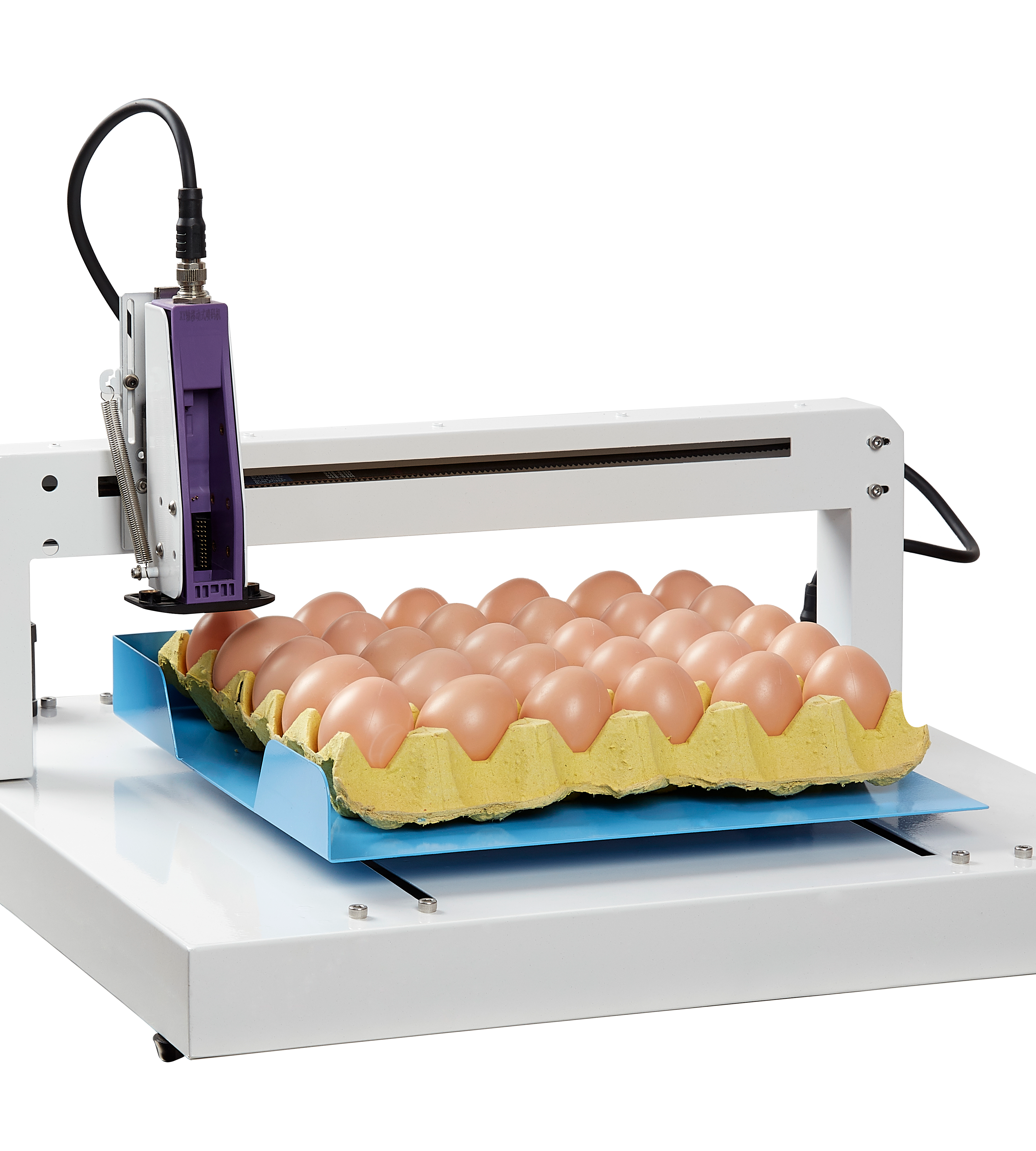

The BTMARK Egg coding machine is equipped with advanced technology for egg production lines to give accurate and effective coding solutions. It is a reliable innovation that works well with different types of eggs specified in terms of quality or any other factor. No matter whether they are organic, fresh or processed goods this product ensures that there is clear and long-lasting labelling on them. Easy to use, friendly interface and stability in performance will increase output significantly while saving time too. The complexity of your demands does not matter because our system can handle all these tasks thus making it possible for the line work efficiently at higher levels than ever before so that you achieve excellence in standards set forth by supervisors along the way.

For egg producers worldwide, BTMARK egg coding machines can be utilized to increase consumer trust and improve traceability of products, which will set higher benchmarks for quality assurance throughout the industry. The ability of these devices to print readable codes directly onto egg shells without damaging them is made possible by their employment of state-of-the-art inkjet printing technology that is more advanced than any other similar product currently available on the market.The BTMARK machine supports printing dynamic data so it can keep pace with real-time changes in information and be easily integrated into ERP systems if necessary. Moreover, among other things also reliable but food safety required compliant egg coding solution system from BTMARK should make efficient operational process more effective as well.

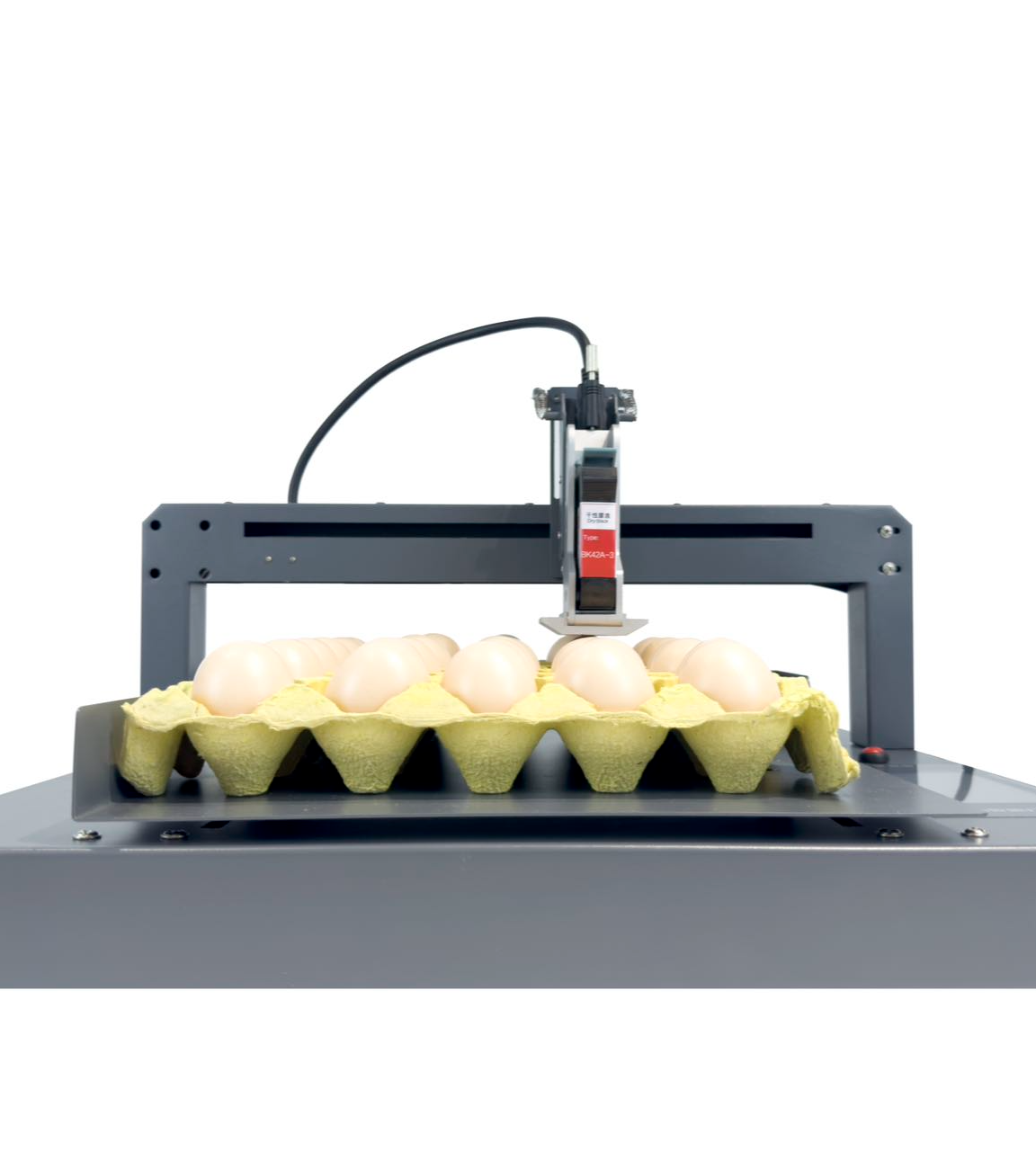

Satisfy precisions egg coding with BTMARK technology which has been developed according to the strict demands of egg producers and suppliers. They have adopted sophisticated print control systems in their machines that help them put codes accurately on eggs that are different shapes and sizes. So as to maximize the efficiency as well as keep our egg coding machines up all the time, operators should be trained which is what these support programs were designed for but it does not end there because they also enable them do that through a wider range of skills too. Trust us when we say this: no other company can offer such an array or variety of approaches towards solving problems related to packaging eggs; therefore making products more visible while at the same time increasing consumer confidence levels not only in your brand but also about its safety standards too – BTMARK guarantees it!

BTMARK offers superior egg coding machine solutions that target the specific difficulties encountered when marking eggs in agricultural and food processing sectors. Our systems incorporate latest innovations so as to enable accurate and speedy printing of batch numbers, sell-by dates, and logos on the eggs themselves. These machines are built tough and easy-to-use too; they seamlessly fit into any already established production line thereby improving traceability as well as conformity with set rules. Rely on BTMARK for trustworthy answers that will help you increase productivity levels while maintaining high standards in packaging and delivering eggs.

To reduce environmental impact and at the same time meet the rules, BTMARK provides sustainable solutions for marking eggs. Our machines for coding eggs use energy-saving technologies and eco-friendly inks which foster sustainability in production and packaging practices of eggs. In agriculture, these egg coding devices from BTMARK are made with sturdy designs that can withstand diverse printing needs thus reducing wastage while optimizing resource utilization. Opt for dependable performance-oriented green alternatives – choose BTMARK.

BTMARK specializes in offering professional coding and marking services globally, focusing on efficient and intelligent inkjet marking systems. With 21 years of experience in developing and manufacturing identification systems, the company has secured numerous patents and CE certification from the EU. BTMARK has successfully implemented anti-counterfeiting measures, anti-channeling management, remote operation, and production identification, resulting in reduced labor input on production lines and catering to the needs of fully automated factories.

High-precision laser coding suitable for various packaging materials.

Convenient handheld coding device ideal for small-batch production.

Designed specifically for eggs, achieving clear and durable markings.

Versatile inkjet printer suitable for various surfaces and environments.

An egg coding machine is specifically designed for marking eggs with essential information such as production dates, batch numbers, and logos. It ensures traceability throughout the supply chain, enhances product safety, and helps comply with regulatory requirements. This capability is crucial for egg producers aiming to maintain quality assurance and meet consumer expectations.

Egg coding machines utilize specialized inks and printing technologies that adhere well to eggshells. They often employ non-contact printing methods like inkjet technology, ensuring clear, legible codes without damaging the delicate surface of the egg. These machines are calibrated to operate efficiently in egg production environments, delivering consistent results.

Egg coding machines can print various alphanumeric codes, QR codes, barcodes, and graphics directly onto eggshells. These codes can include production dates, best-before dates, farm information, and other customized data required by producers to track and manage their egg inventory effectively.

Integrating an egg coding machine into production lines automates the coding process, reducing the need for manual intervention and minimizing errors. This automation speeds up production, enhances workflow efficiency, and allows producers to handle larger volumes of eggs consistently. It also facilitates real-time data management and traceability, crucial for quality control and compliance.

When selecting an egg coding machine, factors such as print quality, speed, ease of maintenance, compatibility with egg handling systems, and the supplier's technical support capabilities are essential. It's important to choose a machine that meets specific industry standards and regulatory requirements while integrating seamlessly into existing production setups to maximize operational efficiency.

©Copyright 2024 Shenzhen Yungchia Inkjet Equipment Co.,Ltd. all rights reserved | Privacy Policy