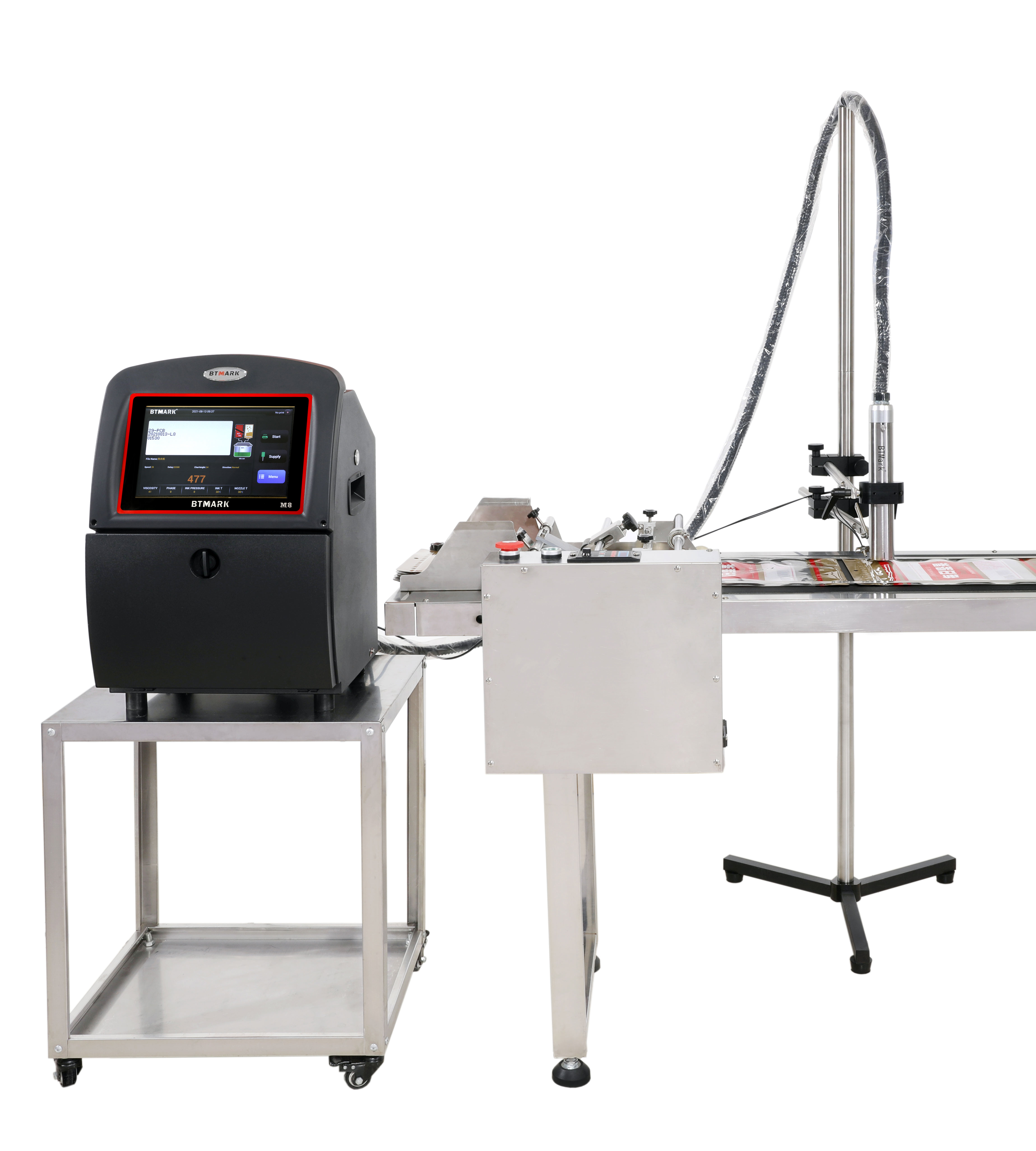

BTMARK Inkjet Coding Machine uses cutting-edge inkjet technology for precise high-speed printing on all types of industrial production lines. It is made to mark any kind of material in any environment; this can be food packagings, pharmaceutical labelings or electronic components among others with the aim of ensuring legible and long lasting identification marks on products. It is highly user friendly and stable thereby enhancing productivity levels. It doesn’t only print accurate dates or batch numbers but also caters for more intricate requirements during manufacturing thus becoming an indispensable tool for ensuring quality control through proper labeling along your production chain.

Attain trusted performance with BTMARK inkjet coding technology which is known for its accuracy and endurance in industrial environments. Our printing machines have been designed to run non-stop identifying labels while maintaining a good quality print as well as meeting set regulations. At BTMARK we value creativity and customer contentment thus presenting you with expandable inkjet coders that will suit your needs as the business grows. With strong structure and dependable operation of our ink jet coding systems from BTMARK, you can be worry free when marking packages containing food or drugs among other things like pharmaceutical labels since they work perfectly every single time!

BTMARK is at the forefront when it comes to inkjet coding technology. This means that they offer creative answers for current manufacturing requirements. The latest print heads and ink systems are used in our machines which guarantees consistent and reliable performance throughout; moreover they have been designed with state-of-the art technology so as to ensure this happens. BTMARK machines are made precise and long-lasting hence able to give clear prints even under tricky production conditions where other brands fail to work well because of their fragility or lack thereof. Whether cosmetics, electronics or automotive parts need marking; BTMARK provides customization options that can improve visibility around the brand while also aiding in product recognition.

Discover industrial marking systems by BTMARK, which are the most accurate and reliable precision inkjet coding machines on the market. Our devices use state-of-the-art print head technologies to produce high-definition prints on different materials like plastic, metal or packaging substrates. BTMARK ink jet printers can be easily integrated into any production line because they have been designed for that purpose; this means that they can print batch codes, QR codes, expiry dates among other things wherever required along a manufacturing process. Choose us if you need creativity in your product traceability system development because we provide innovative solutions that meets international standards across all industries where goods are produced.

To confront the ever-changing requirements of industrial coding applications, BTMARK created inkjet coding machines to provide more features than ever before. Our machines include fast-replace ink cartridges and automated maintenance programs which significantly reduce downtime while improving operational efficiency. These printers have multi-line print capability as well as variable data input compatibility which allows for easy handling even complex coding needs. Our technical support is second-to-none; we offer complete training backing all our products so customers can get the most out of their investment in an inkjet coding system from us.

BTMARK specializes in offering professional coding and marking services globally, focusing on efficient and intelligent inkjet marking systems. With 21 years of experience in developing and manufacturing identification systems, the company has secured numerous patents and CE certification from the EU. BTMARK has successfully implemented anti-counterfeiting measures, anti-channeling management, remote operation, and production identification, resulting in reduced labor input on production lines and catering to the needs of fully automated factories.

High-precision laser coding suitable for various packaging materials.

Convenient handheld coding device ideal for small-batch production.

Designed specifically for eggs, achieving clear and durable markings.

Versatile inkjet printer suitable for various surfaces and environments.

An Inkjet Coding Machine is an advanced printing solution used to mark products with alphanumeric codes, logos, barcodes, and other information directly onto surfaces such as packaging materials, plastics, metals, and more. It operates by propelling tiny droplets of ink onto the surface through a nozzle, offering fast and precise printing without contact, making it ideal for high-speed production lines.

Inkjet Coding Machines offer several advantages including high-speed printing capabilities, ability to print variable data like batch numbers and expiration dates, non-contact operation which prevents damage to sensitive products, and versatility in marking on different substrates. They enhance efficiency, reduce production costs associated with labeling, and ensure accurate traceability throughout the supply chain.

Inkjet Coding Machines play a critical role in ensuring product traceability by marking items with clear, permanent codes that include essential information required for tracking throughout the manufacturing and distribution process. This capability helps manufacturers comply with regulatory standards and consumer safety requirements by providing accurate labeling and identification of products.

When choosing an Inkjet Coding Machine, key considerations include print resolution and quality, printing speed, ink adhesion to various substrates, ease of integration into existing production lines, maintenance requirements, and the supplier's technical support and service offerings. It's important to select a machine that aligns with specific production needs and regulatory requirements to optimize operational efficiency.

Integrating Inkjet Coding Machines into production lines automates the marking process, reducing reliance on manual labor and minimizing errors associated with traditional labeling methods. This automation improves workflow efficiency, accelerates throughput, and reduces production downtime, ultimately enhancing overall cost-effectiveness and productivity in manufacturing operations.

©Copyright 2024 Shenzhen Yungchia Inkjet Equipment Co.,Ltd. all rights reserved | Privacy Policy